Mass transit industry – Face-Plate Diaphragm

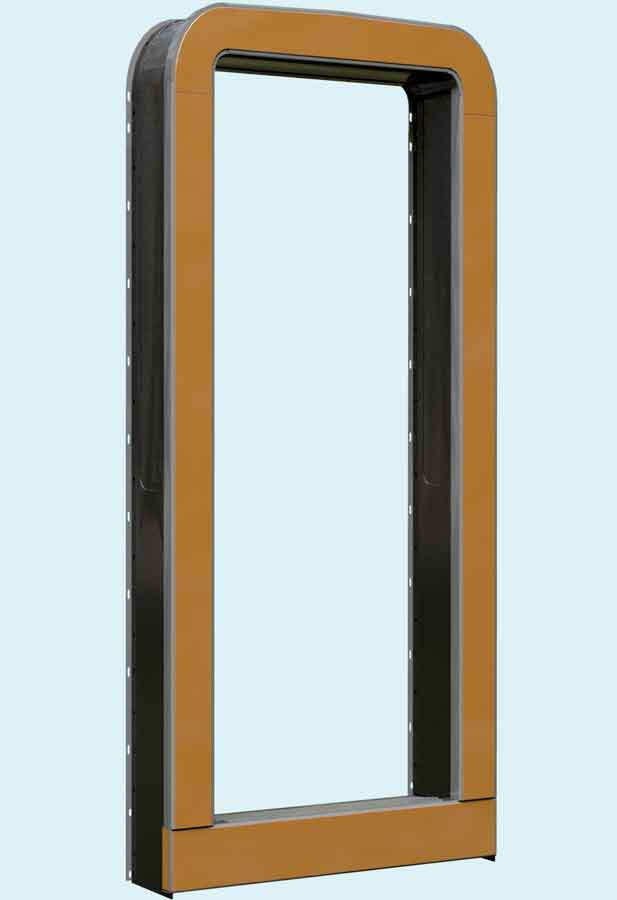

Face Plate diaphragm

The Face Plate diaphragm is our mid-range model and uses time-tested technology that has proven its reliability on intercity railway cars for nearly 40 years.

It is made from an elastomer that meets the mass transit industry’s fire, smoke, and toxicity standards.

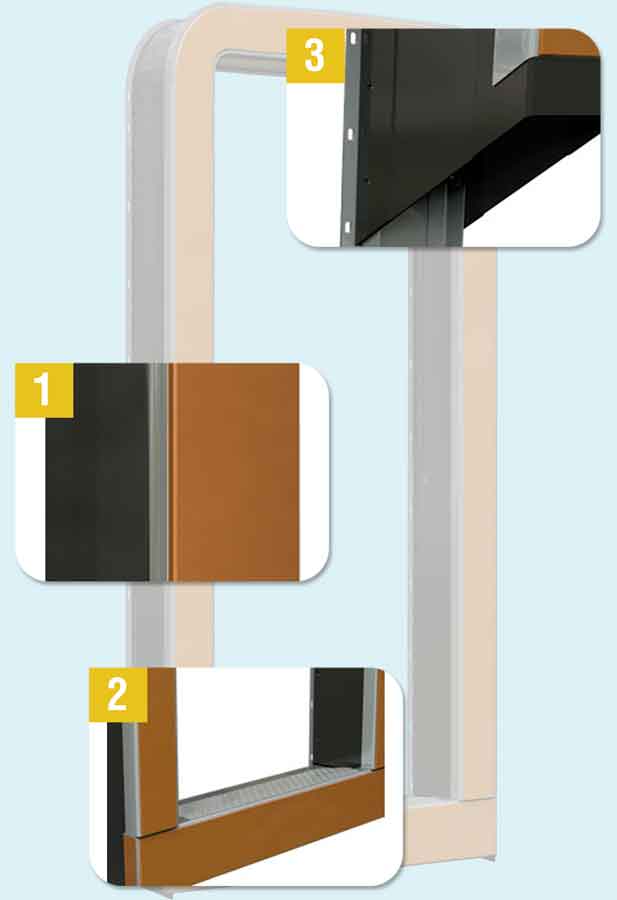

1 A plate coated with a phenolic compound is installed at the front to increase durability.

2 Car sills are equipped with shear mount rubber shock absorbers.

3 The diaphragm is moulded as a single, seamless part using our time-tested Flex 35 neoprene that meets the mass transit industry’s fire, smoke, and toxicity standards.

Place the mouse on the diaphragm image to see more details.