Rubber and silicone moulding

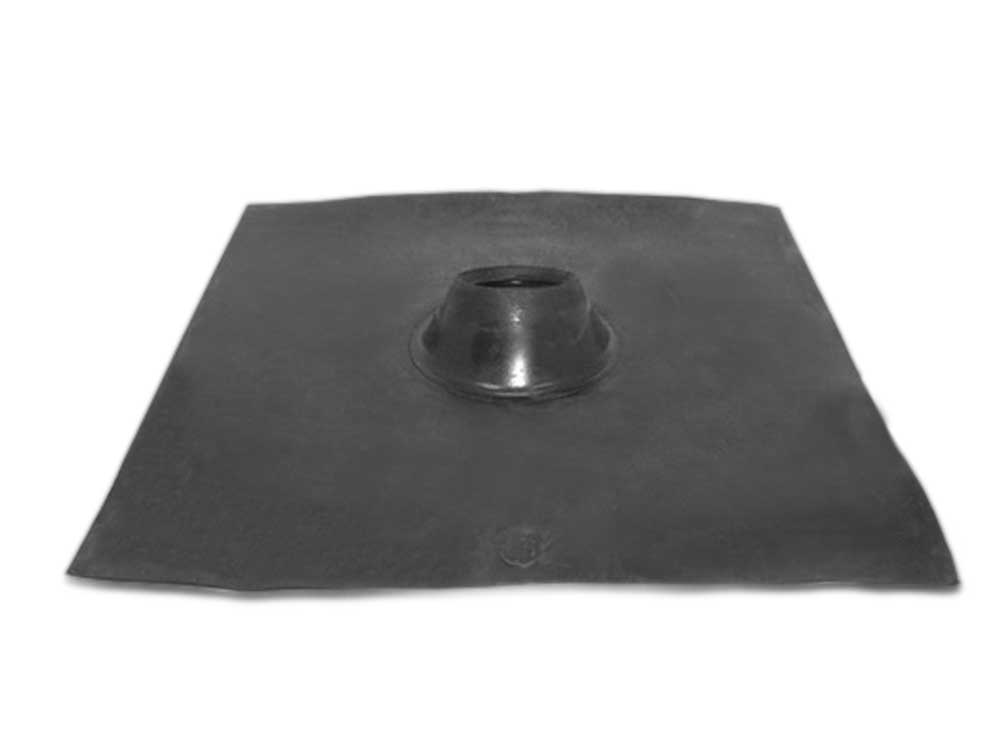

To mould rubber products into the desired shape and give them the required properties, Pro-Flex Rubber combines specific elastomers in moulds inserted into hydraulic heat presses of various size. This process is referred to as compression moulding.

Rubber injection moulding

Pro-Flex Rubber uses rubber injection moulding to manufacture parts with various mechanical functions and properties. The rubber compound is injected into a heated barrel and funnelled into a mould cavity where it is cured and hardened in the desired shape.

This manufacturing process use two different types of injection moulding: injection in either closed moulds or open moulds. Closed moulds are used to manufacture parts such as plumbing seals and gaskets, and open moulds are used to manufacture junctions by overmoulding one or several elements together to create window corner joints; for railway cars, for example.

Pro-Flex Rubber also offers rubber and silicone injection splicing solutions to manufacture finished products.

Rubber compression moulding

Rubber compression moulding is an efficient and economical manufacturing method to give the desired shape to elastomer products, particularly with low production volume. The Pro-Flex Rubber team has the necessary expertise to mould or overmould rubber and silicone of all colors.

Read about Pro-Flex’s rubber compression moulding capacity.

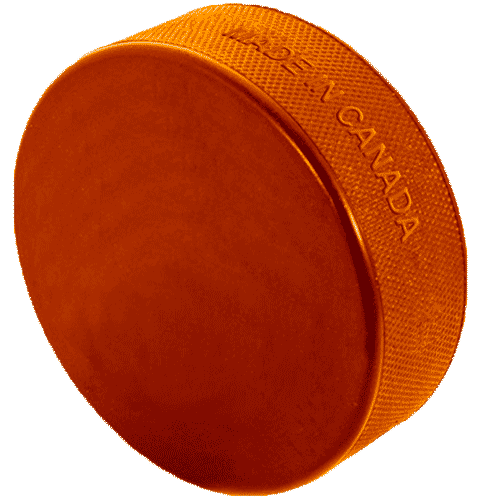

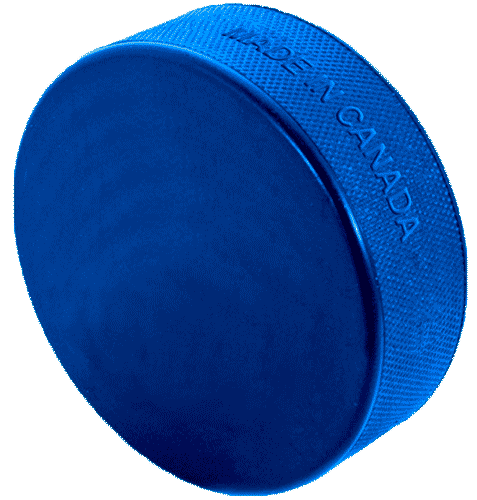

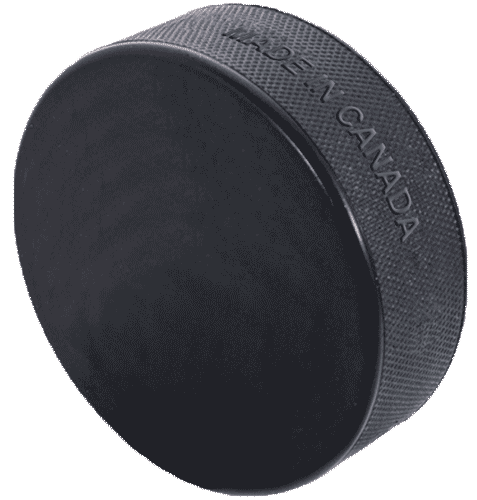

100% Canadian Hockey Pucks

Thanks to our new acquisition, we now have the production capacity to meet any type of order for hockey pucks. Whatever kind of hockey puck is desired, our compression moulding process can use standard moulds or completely customized moulds. In addition, the type of rubber used to manufacture our hockey pucks makes printing easier. Our engineering department can help you develop your own mould. Choose 100% Canadian hockey pucks proudly made in our Canadian manufacturing plants.

Rubber transfer moulding

Rubber moulding capacity

Rubber injection moulding

Three injection moulding presses:

- two 27-tonne injection moulding presses

- one 40-tonne injection moulding press

Rubber compression moulding

Ten compression moulding presses with different surface areas:

- 42’’ X 42’’

- 22’’ X 96’’

OVERSIZED PARTS

Pro-Flex Rubber has two presses specifically designed to mould very large parts to meet the needs of most of our customers.

INTEGRATING / OVERMOULDING

Pro-Flex Rubber has expertise in rubber overmoulding metal and plastic inserts, providing comprehensive solutions ranging from design, sourcing of sub-parts, moulding, assembly, and product certification.