Mass transit industry – Accordion Diaphragm

Accordion diaphragm

Pro-Flex Rubber, together with the Centre de Recherche Industrielle du Québec (CRIC) industrial research centre, has tested its diaphragms in climate-controlled chambers. Our field-tested, high-performance diaphragms meet our clients’ requirements. Accordion diaphragms are hand-assembled and sewn with a special Kevlar thread.

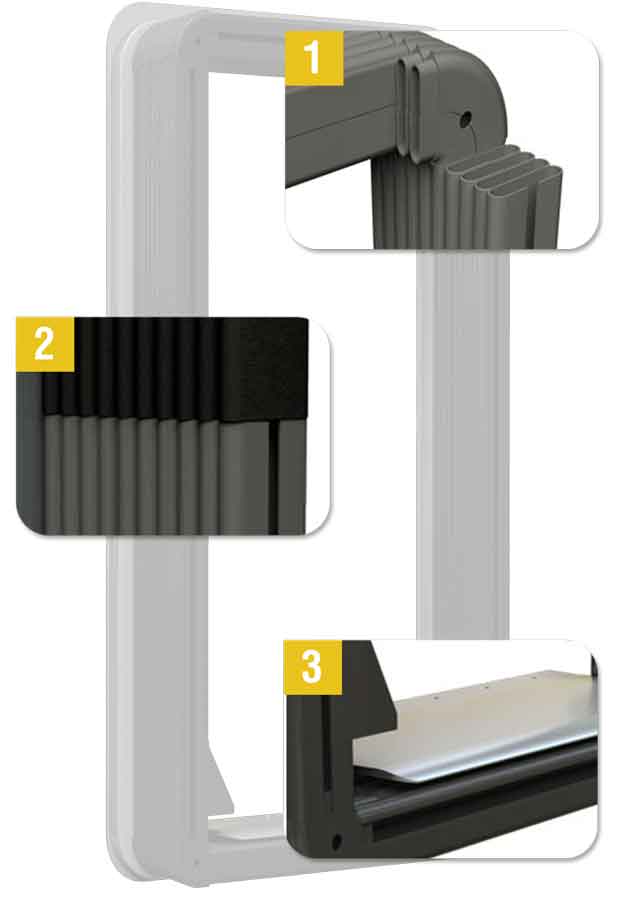

1 Corners are compression moulded prior to assembly.

2 Bellows are assembled side by side to create the diaphragm.

3 Car sills are made-to-measure to ensure passenger safety between railway cars.

Place the mouse on the diaphragm image to see more details.

ONE-PIECE Accordion diaphragm

This type of diaphragm is used on certain models of light urban trains manufactured by Siemens in Sacramento, California. The ONE-PIECE Accordion diaphragm, seamless membrane is moulded on our 96-inch press.

View our other specialized public transit products

Face-Plate Diaphragm

Tubular Diaphragm

Connectors, rubber insulations and rubber seals

Mass transit projects

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.